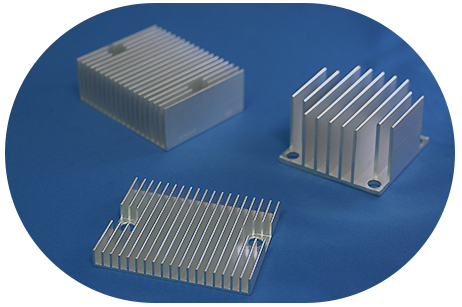

Machining

Different from industrial competitors, WPG’s precision machining capabilities are adapted to a wide range of materials and provide quick turnaround and volume scalability. Our committed investment to top-notch machinery and measurement instruments, made in Germany and Japan, enables us to supply tools and parts to manufacture some of most well known technology products in the world. Our equipment list includes DMG 5-axis vertical turning, HAWEMAT tool grinders, Okuma CNC lathes, ANCA tool grinders and Helitronic tool grinders. Machining provides small quantities requires accurate form, fit and function. It’s great for prototypes, functional tests, jigs and fixtures.

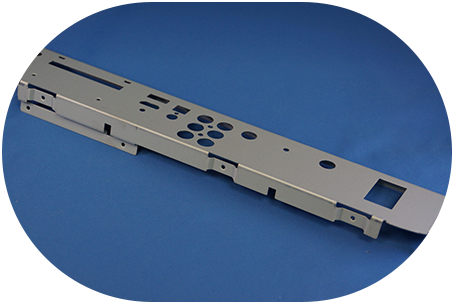

Metal Stamping

Our high quality metal stamping is ISO14001 and TS16949 certified. Presses range from 10 to 800 MT, progressive and transfer dies. Since 1995, we’ve served customers across industries and geography: automotive, telecom, home appliance, electronics, and sporting goods.

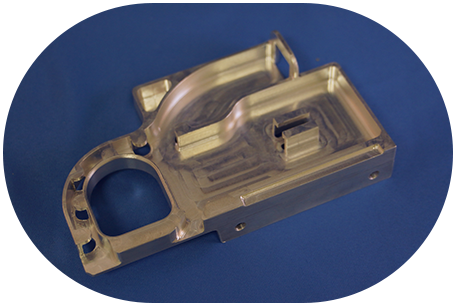

Plastic Injection

We have set goals of maintaining production and quality while supplying the industry with very competitive pricing and adjustable on-time delivery. With 100 plus injection molding machines and robot systems, Well Group Products is looking forward to meeting the changing needs of our customers.

Product Assembly

We have dedicated assembly lines tailored to customer specifications.

- 8 + 3 hours / shift

- 3 shifts / day

- 24 / 7 operation

- Less than 1/2 hour set up & quick turn operations

- Project management oriented

Quick Turnaround & Prototyping

Well Group stands out in the industry as a provider of rush production prototype and short run products. Our engineers work relentlessly with customers to identify cost-saving approaches and maximize efficiency in the development and production of prototypes. Our engineers assist customers at the NPI stage in selecting materials and designing tooling that translates into the highest quality first-piece samples and prototypes.